By Kaitlin McHenry

At Lavender Hill Farm, we distill our fresh lavender on-site to produce lavender essential oil! Our distillation season begins in early to mid-July and runs through mid-September, using our antique copper still affectionately named “Penny.” Through steam distillation, the oil is gently extracted from the plant material and collected as it condenses, capturing the pure essence of lavender.

Harvesting for the best possible essential oil starts in the field. The amount of oil per unit of plant material varies by lavender cultivar and bloom timing. We have thirty cultivars of lavender on our farm, but we don’t use all of them for essential oils. Our favorites for essential oil production include Dwarf White, Miss Katherine, Melissa, Violet Intrigue, and Grosso. The French hybrid cultivars (Grosso) produce more oil compared to the English cultivars, but all of them have very unique scents.

The English oil tends to be sweeter and milder, while the French hybrids have a stronger scent due to higher camphor content in the oil. The timing of harvest is important to oil production. Harvesting too early or too late leads to lower oil outputs. We aim for when 30% to 60% of the blooms are open on the plant for peak oil. While the oil content is still high when 100% of the blooms have opened, the clock is ticking, and the risk of weather aging the blooms increases. A heavy rain on a fully bloomed lavender plant can shorten the bloom period and reduce the time left to harvest for the highest oil outputs.

When harvesting for essential oil, we cut shorter stems compared to when we harvest for drying bunches. This is because the highest concentration of oil is in the buds (there’s still some in the stems though). The freshly harvested lavender is collected in buckets and brought straight to the Stillhouse. Dried lavender can be used for oil distillation, but we generally skip the drying process to save on time and materials.

Let’s take a look at our still, “Penny”!

- The Pot

- The Basket

- The Onion

- The Condenser

The whole until can be taken apart to allow for adding water and lavender.

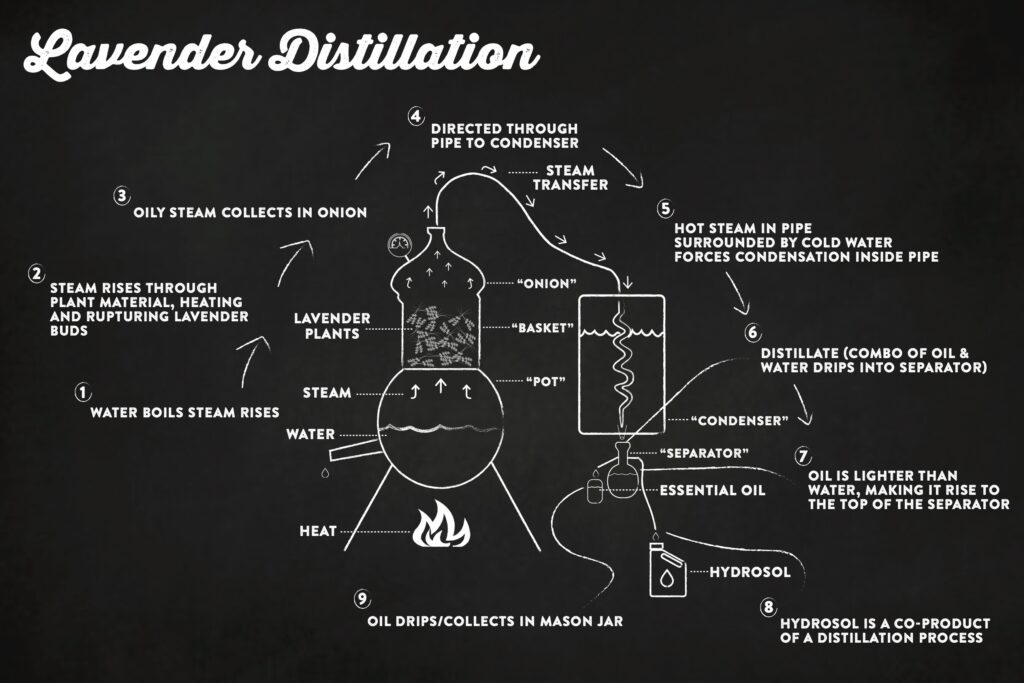

The bottom section is called “the pot”. We add five gallons of water to the pot that will be heated to a boil with a propane burner.

The middle section is called “the basket”. This is where the lavender is packed into the still. The basket has a screened bottom to allow steam to rise up, while preventing lavender from falling into the pot. We pack between four and five (17 gallon) buckets into the basket. We pack the lavender very tight so it will trap the steam on its way up. The steam takes a long time to work through the tightly packed lavender, and in the process, it heats the buds up to the point where they burst and release lavender oil. Water boils at 212°F and lavender essential oil boils at approximately 180°F, so the steam heats the lavender to the point where the oil becomes a gas.

The oily steam rises up into the next section, “the onion”. The onion guides the steam into a pipe that leads to “the condenser”.

The condenser is filled with cold water, and the pipe connects with a coil submerged in the cold water. As the hot steam enters the cold coil, it begins to cool and sweat on the inside of this coil. The sweat collects and flows down until it exits the condenser as a liquid we call “lavender distillate”. The distillate is collected in a special separator jar. It’s not pure essential oil yet. It’s a mixture of oil and water, but it does not take long for non-polar oil and polar water to separate and gravity to help the process. Since oil is less dense than water, a layer of oil builds above the water. The separator is specially designed so only the oil can climb the neck of the jar and flow out into an awaiting mason jar.

The bottom layer of water, which still contains a small percentage of essential oil, exits the separator through a different tube (right), and is captured in glass gallon jugs. This water is a floral water we call lavender “hydrosol”. Hydrosol is the same pH as our skin, and it has anti-inflammatory and anti-microbial qualities, similar to lavender oil. It is great for any skin irritation or abrasion including cuts, scrapes, bug bits, bee stings, poison ivy, sunburn, shingles, acne, eczema, and more. It is also a favorite product within the Lavender Hill Farm staff!

The whole process takes about an hour from loading the still with lavender to turning the burner off. We could keep running the still longer for more oil, but the quality starts to degrade after an hour. We make sure that we keep our product of the highest possible quality. On average, one mason jar (200ml) of essential oil is produced per run. Depending on the variety and the bloom time, this can vary from less than one jar to up to five jars. The process can be compared to maple syrup: forty gallons of tree sap makes approximately one gallon of maple syrup. It takes a lot of material for a small amount of product, but it is a very pure and concentrated version of the original plant material!

Lavender Essential Oil and Lavender Hydrosol can be purchased online and at the Farmhouse Boutique.